PRODUCT CATEGORY

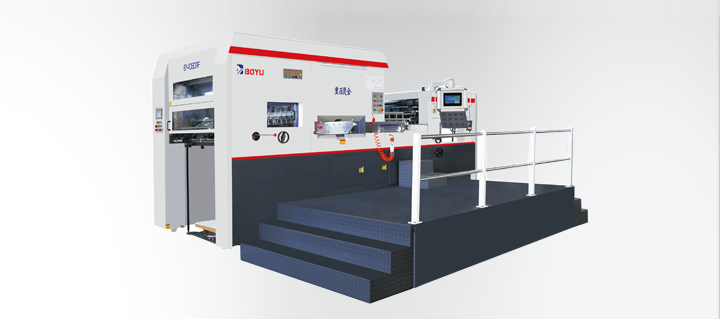

BY-1080RF Automatic... machine

.

Technique characteristics

•Equipped with two longitudinal foil shafts,which makes foil stamping process mae reasonable.

•The unwinding and rewinding way for longitudinal foil feeding device is in accordance with the running directbn of gripper bars,which is easy for operation, foil saving and suitable for the separation fa paper from foil.

•There are inside and outside foil rewinding ways available fa customer to choose.

•This machine is a high stnxture design, which reduces the floor space.

•The speed of cardboard is up to 7500 S/H, the speed of corrugated paper is 6000S/H, and the diecutting precision is ± 0.1mm.

•There are 6 heating temperature zones at the upper platform, the temperature of each zone can be individually adjusted, it is widely used for the hot embossing, creasing, and other hot pressing process.

•With four-sucking, five-conveying suckers, the feeding head can suck powerfully, convey steadily, and the suckers can be adjusted with non-stop running following the status of paper for suction height, angle and suction air flow, to achieve thicknesss of balance, smooth and accurate feeding.

•Pre-stacking paper mechanism, main and auxiliary paper feeding device achieve non-stop feeding.

•Electrical system adopts PLC computer program controller. There are human-machine interfaces at the operating side, delivery side, which monitor the operating conditon of machine, troubles, input and output points of PLC, easy to operate.

•Four sensors are equipped at the front lay, to check the right-position precision of paper and avoid waste.

•The left and right side lays are installed, It has two functions of push and pull, easy to change. The position and pressure of side lay is adjustable to coincide with the paper of different size and thickness, and the sensas on them can detect the right-position precision of paper all the time.

•Using 230℃ large stroke angle intermittent mechanism, which ensures the machine to run smoothly with high speed.

•It is adopted imported pneumatic clutch, FM motors, brake smoothly.

•The hot embossing, diecutting frame and diecutting steel plate adopt plate-locking system, easy operatbn and with high precisbn.

•The hot embossing plate and diecutting frame can be replaced, in ader to achieve the conversion function of embossing and diecutting.

•The unwinding and rewinding way for longitudinal foil feeding device is in accordance with the running directbn of gripper bars,which is easy for operation, foil saving and suitable for the separation fa paper from foil.

•There are inside and outside foil rewinding ways available fa customer to choose.

•This machine is a high stnxture design, which reduces the floor space.

•The speed of cardboard is up to 7500 S/H, the speed of corrugated paper is 6000S/H, and the diecutting precision is ± 0.1mm.

•There are 6 heating temperature zones at the upper platform, the temperature of each zone can be individually adjusted, it is widely used for the hot embossing, creasing, and other hot pressing process.

•With four-sucking, five-conveying suckers, the feeding head can suck powerfully, convey steadily, and the suckers can be adjusted with non-stop running following the status of paper for suction height, angle and suction air flow, to achieve thicknesss of balance, smooth and accurate feeding.

•Pre-stacking paper mechanism, main and auxiliary paper feeding device achieve non-stop feeding.

•Electrical system adopts PLC computer program controller. There are human-machine interfaces at the operating side, delivery side, which monitor the operating conditon of machine, troubles, input and output points of PLC, easy to operate.

•Four sensors are equipped at the front lay, to check the right-position precision of paper and avoid waste.

•The left and right side lays are installed, It has two functions of push and pull, easy to change. The position and pressure of side lay is adjustable to coincide with the paper of different size and thickness, and the sensas on them can detect the right-position precision of paper all the time.

•Using 230℃ large stroke angle intermittent mechanism, which ensures the machine to run smoothly with high speed.

•It is adopted imported pneumatic clutch, FM motors, brake smoothly.

•The hot embossing, diecutting frame and diecutting steel plate adopt plate-locking system, easy operatbn and with high precisbn.

•The hot embossing plate and diecutting frame can be replaced, in ader to achieve the conversion function of embossing and diecutting.

Specifications

| Max. paper | 1080×780mm |

| Min. paper | 400×370mm |

| Max. speed |

7000S/H(CARDBOARD) 6000S/H(CORRUGATED PAPER) |

| Max. pressure | 600t |

| Max.stamping speed | 6000 s/h |

| Precision | ±0.1mm |

| Min. gripper edge | 6mm |

| Feeding pile height | 1500mm |

| Delivery pile height | 1500mm |

| Heating zone | 6 |

| Heating plate temp | 40~190℃ |

| Fax.foll stamping size | 1070X770mm |

|

Feeding shaft for

foil feeding,longitudinal

|

2 |

| Machine weight | 17500kg |

| Dimension | 5450×2300×2800mm |

Local introduction

-

Feeding unit

Feeding unit -

Lubricating system

Lubricating system -

Interface

Interface -

Hot embossing & diecutting unit

Hot embossing & diecutting unit -

Delivery unit

Delivery unit -

Electric unit

Electric unit -

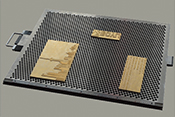

Honeycomb plate

Honeycomb plate -

Prodct

Prodct

中文

中文 ENGLISH

ENGLISH